The OG202 Tooke Paint Inspection Gage/Gauge II is a precision tool for inspection and thickness measurement (in accordance with ASTM D4138) of single or multiple coats on any substrate, and for microscopic observation and measurement of substrate and film defects. The OG202 Tooke Paint Inspection Gage/Gauge II uses an illuminated 50-power microscope with measuring reticle, and mounts tungsten carbide cutting tips for precise incision of the work surface. Direct measurement of total coating thickness and thickness of individual coats of paint is a unique capability of the Tooke Paint Inspection Gage/Gauge. Thus, in addition to routine use, the OG202 Tooke Paint Inspection Gage/Gauge II often serves as a “referee” instrument to calibrate indirect or non-destructive thickness measuring instruments. Other uses include assessment of substrate conditions and coating adhesion, and observation of microscopic cracking, tendency for brittleness, cratering, or other microscopic film symptoms.

Operation

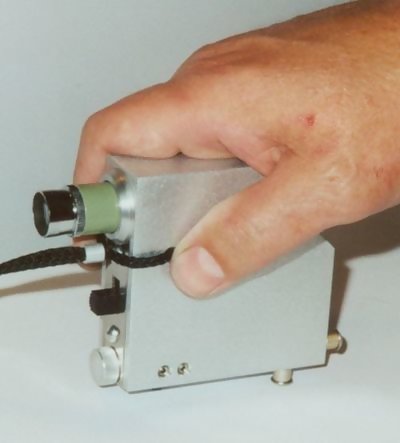

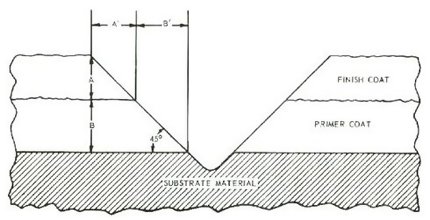

A special cutting tool (the “cutting tip”) that is integral to the gage is used to incise a small precision V-groove through the paint film and into the substrate. Incising the V-groove with the OG202

|

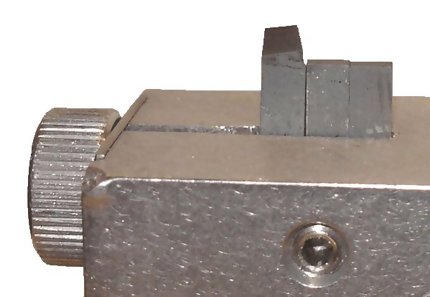

Micro-Metrics Company cutting tips are precision-ground by hand from tungsten-carbide blanks in a multiple-step process that includes a final inspection by microscope for accuracy of angle, fineness of finish, and lack of chips and damage The gage in standard configuration mounts 1×, 2×, and 10× cutting tips. An optional 5× tip is available. The gage can also be ordered with three tips of the same size or in any desired configuration (including a single cutting tip with two non-functioning blanks). | The tip slot is marked for the standard tip arrangement |  |

Close-up of a non-standard arrangement of tips;

a 1× tip extended for use and two blanks |  |

Principle

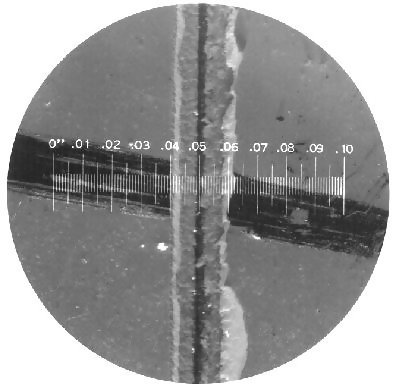

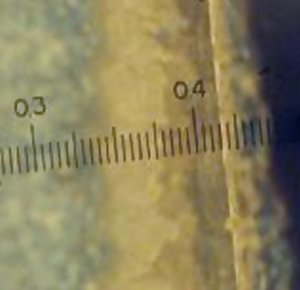

The incised V-groove is observed vertically through an illuminated microscope bearing a measuring reticle (scale). An “English” (Imperial) version, with the reticle marked in mils, and a metric version, with the reticle marked in microns, are available. | The view through the English microscope |  |

English Reticle Specifications

CUTTING

TIP | MAXIMUM

COATING

THICKNESS | PRECISION OF

THICKNESS

DETERMINATIONS | ONE DIVISION ON

THE RETICLE SCALE

REPRESENTS: |

|---|

| 1× | 100 mils | ± 0.25 mils | 1.0 mil | | 2× | 20 mils | 0.13 mils | 0.5 mil | | 10× | 1.0 mil | 0.025 mils | 0.1 mil |

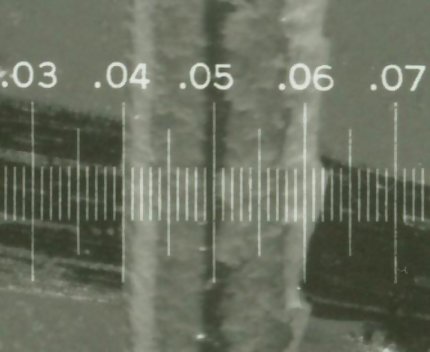

| An enlargment of the (English) reticle view showing the divisions |  |

Metric Reticle Specifications

CUTTING

TIP | MAXIMUM

COATING

THICKNESS | PRECISION OF

THICKNESS

DETERMINATIONS | ONE DIVISION ON

THE RETICLE SCALE

REPRESENTS: |

|---|

| 1× | 2500 μm | ± 5 μm | 20 μm | | 2× | 500 μm | ± 2.5 μm | 10 μm | | 10× | 75 μm | ± 0.5 μm | 2 μm |

| An enlargment of the (metric) reticle view showing the divisions |  |

| The geometry of the OG202 Tooke Paint Inspection Gage incision |  |

Special Applications

The OG202 Tooke Paint Inspection Gage/Gauge has been used to assess sandblast cleaning work, to measure plating and paint thickness on ceramics, metal, wood, and concrete, and even to measure protective backing thickness on mirrors. It is virtually the only tool for measuring paint on plastics. The quality of the incision in the film discloses much about the characteristics of the brittleness and adhesion of the material.

Shipping Specifications

| Material | Machined aluminum body | | Overall dimensions | 4.5" x 3.5" x1"

11.4 cm x 8.9 cm x 2.5 cm | | Microscope | 50-power, 45-degree, illuminated | | Power | Two 15V AA drycells | | Lamp | Penlight bulb, #222GE | | Cutting tips | Tungsten-carbide | | Shipping Weight | 2 pounds |

The machined aluminum Tooke Gage/Gauge comes in a case with strap, spare batteries and bulb, marking pen, hex wrench and a technical data sheet. Standard cutting tips are 1×, 2×, and 10×. |